In the realm of mechanical manufacturing and hydraulic systems, the intricacy of connections is pivotal for ensuring a leak-free and efficient operation. Among the various types of threading used to forge these crucial connections, National Pipe Thread (NPT), National Pipe Straight (NPS), and National Pipe Straight Mechanical (NPSM) are prominent. This article delves into the nuances of these threads, shedding light on their applications in hydraulic fittings, and the distinctions among them which are essential for industry professionals to grasp.

The Difference Between of NPT and NPS Threads

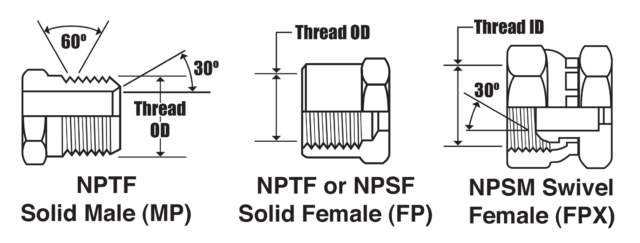

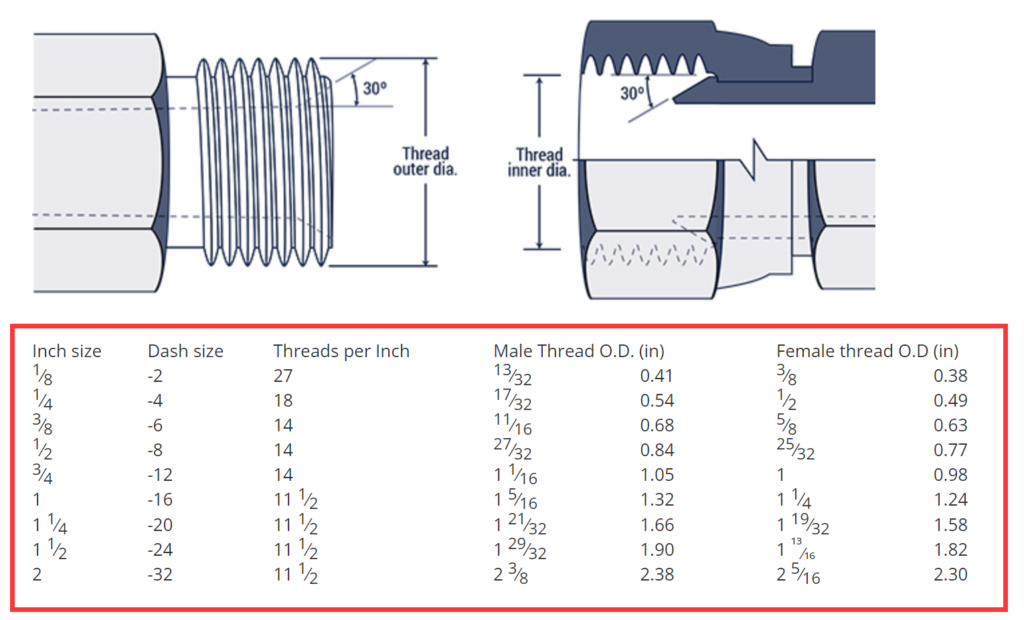

The commonality among NPT and NPS threads lies in their thread angle, shape, and pitch (threads per inch), all of which exhibit a 60° included angle with flat peaks and troughs. However, a discerning eye would notice the taper in NPT threads as opposed to the straight or parallel nature of NPS threads. This fundamental difference influences the sealing mechanism, where the NPT threads form a seal through the interference fit while NPS threads necessitate a gasket or O-ring to achieve a seal. Though NPT and NPS threads can engage with each other, a proper seal isn’t attainable due to their structural differences.

What’s NPSM Thread?

Transitioning to the NPSM threads, a unique design is observed which is often employed in the Female Pipe Swivel fittings. The NPSM thread is crafted with a 60° flank angle, aligning seamlessly with the 30° seat (chamfer) visible down within the swivel nut. This nut, being a permanent fixture to the body, interfaces with a male pipe thread also endowed with a 30° seat (chamfer) at its end. The engineering precision allows the threads to draw both 30° seats (flare and chamfer) together, culminating in a metal-to-metal seal. The 30° seat is a meticulously machined chamfer within the inside diameter of a male pipe thread, distinct from a minor deburr chamfer.

The applications of these threads extend across a plethora of hydraulic assemblies, each serving a distinct purpose. For instance, the NPT threads are favored for their self-sealing prowess in high-pressure scenarios, while the straight threads of NPS and NPSM find their niche in systems where ease of assembly and disassembly is a priority.

Conclusion

In summation, the mechanical manufacturing realm is a theater where the precision of threads such as NPT, NPS, and NPSM plays a starring role. Understanding the intricacies of these threads not only enhances the efficiency and integrity of hydraulic systems but also propels the industry towards a horizon of innovation and reliability. Through the lens of hydraulic fittings, one can truly appreciate the engineering marvel that threads encapsulate, underlining the essence of meticulous design in fostering robust and leak-free connections.

Hydraxio manufacture and supply stainless steel hydraulic fittings with NPT, NPSM and NPS threads. Please contact us for more details.