Find A Reliable Chemical Injection Products Supplier –Hydraxio: Your Trusted Manufacturing Partner

Hydraxio, a foremost manufacturer and supplier in China, specializes in chemical injection products and oilfield parts for the oil & gas industry. With over two decades of experience, we have been serving prominent manufacturers, wholesalers, and distributors of oilfield products across North America.

Our commitment lies in delivering reliable quality, ensuring timely delivery, and providing professional service. For top-quality oilfield products tailored to the oil & gas industry’s needs, please contact our dedicated overseas sales team for further information.

Wholesale Chemical Injection & Oilfied Products Supplier: Quality, Stability, and Performance You Can Depend On

At Hydraxio, our chemical injection and oilfied products not only meet but also exceed internationally recognized standards such as SAE, JIS, DIN, and ISO. Trust in our dedication to excellence, as we provide oilfied products that set the industry standard.

- Wholesale Price

- Stable Performance

- Quality Raw Materials

- CAD Drawings & Technical Support

- Compliance with International Standards

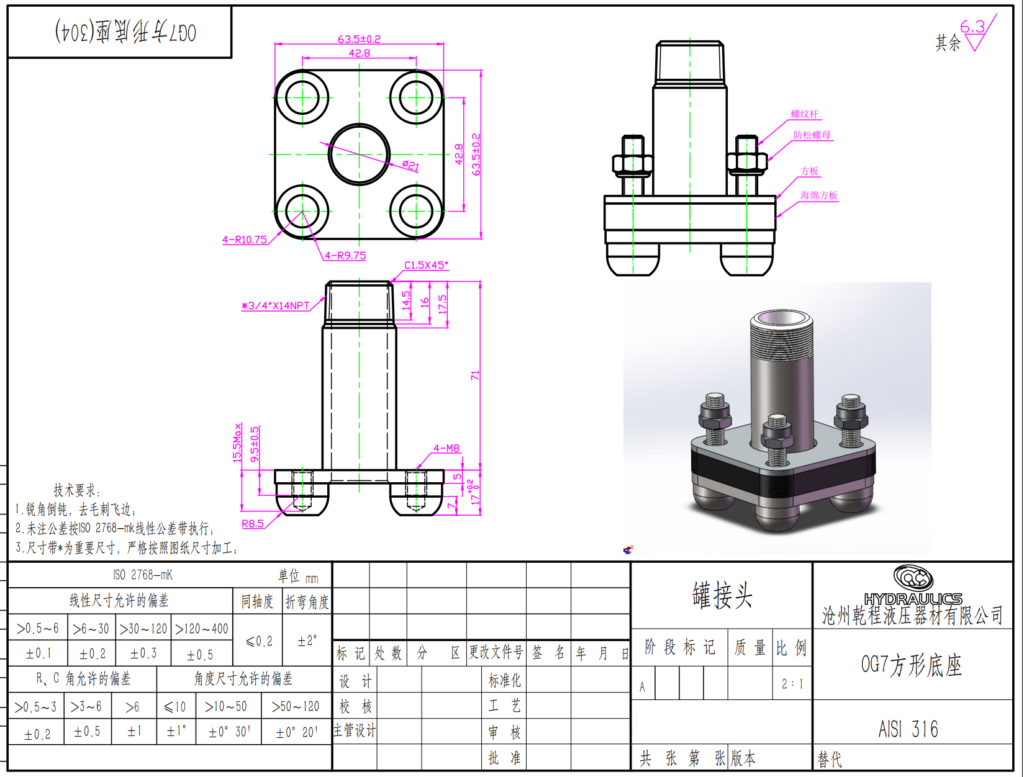

Stainless Steel Tank Bulkhead Fittings

Hydraxio supplies stainless steel bulkhead fittings for Poly or Cross-Link chemical tanks. Made from a no weld tooling system with high quality 316 stainless steel and comes fitted with a proven no leak gasket.

- Size: 3/4″, 1″ and 2″

- Gasket: EPDM and XLPE

- Thread: NPT

- Material: SS 316/CF8M

- Application: Water, Poly or Cross-Link chemical tanks.

Stainless Steel Ball Valves

Hydraxio has been supplying stainless steel ball valves for years. A Ball valve is a type of shut-off valve that is used to control flow where a simple ‘on’ or ‘off’ flow is required. They are easy to operate and can “shut off” or “open” flow with a simple 90 degree turn of the handle.

- Size: 1/4″-2″

- Type: 1 PC, 2 PC & 3 PC

- Thread: NPT, BSPT, BSPP

- Handle: Locking device handle & Butterfly

- Bore: Full Bore & Reduced Bore

- Pressure: 1000 PSI & 2000 PSI

- Inspection Testing: API598, EN12266

- Medium: Water, Oil & Gas

Stainless Steel Y-Strainer Assembly

Hydraxio offers stainless steel Y-Strainer Assembly that represents a significant advancement in the chemical tank industry, replacing the outdated three-piece system of a Y-Strainer, Tee Fitting, and Butterfly Ball Valve. Made from 316 stainless steel, this high-quality assembly is distinguished by its innovative, one-piece, no-weld design. This ensures enhanced durability and leak resistance, eliminating the risks associated with joint assemblies and traditional welding methods.

- This kit comes with:

- 1) 1/4″ NPT Female Y Strainer

- 2) 3/4″ NPS Female Ball Vavle

- 3) 3/4″ NPT Male Tee Fittings

- Material: SS 316/CF8M

Sight Glass Gauge

Hydraxio’s Site Glass Gauge are aluminum and have a proven engineering that ensures reliable indication and unsurpassed service life. These glass tube flow meters offer an easy-to-read premium glass, making it the ideal choice for chemical products and tanks.

- This kit comes with:

- 1) Sight Glass

- 2) Aluminum Body

- 3)Viton O-Ring Seal

- 4) One 1/4″ NPT Male Adapters, One 1/4″ NPT Male Female Reducer

Stainless Steel InLine Check Valve

Hydraxio supplies Inline Check Valve is manufactured for high quality performance and offers an inexpensive yet effective solution to controlling back flow in high and low pressure fluid systems. Made from high quality 316 stainless steel, this product is rated up to 6000 PSI.

- Size: 1/4″, 3/8″ & 1/2″

- Thread: NPT, BSPT, JIC

- Material: SS 304, SS 316/316L

- O-Ring: FKM/Viton, Buna-N/NBR & Teflon

- Working Pressure: 6,000 PSI & 10,000 PSI

Stainless Steel NPT, JIC Fittings & Adapters

Hydraxio’s stainless steel JIC and NPT fittings and adapters meet SAE and ISO standards, which are interchangeable with Parker & Eaton.

- Size: 1/8″-2″

- Shape: Straight, 45 & 90 Degree Elbows, Tee & Cross

- Thread: JIC, NPT/NPTF, NPSM

- Material: SS 304, SS 316/316L

Stainless Steel Instrumentation Fittings

Hydraxio manufacture and supply stainless steel instrumentation tube fittings that are compatiable with Swagelok and SSP.

At Hydraxio, our stainless steel twin ferrule tube fittings not only meet but also exceed international standards. Specializing exclusively in stainless steel, including AISI 304, AISI 316/316L. Trust in our dedication to excellence, as we provide compression tube fittings that set the industry standard.

- Imperial Size: 1/8″-2″

- Metric Size: 6 mm-25mm

- Shape: Straight, 45 & 90 Degree Elbows, Tee & Cross

- Thread: JIC, NPT/NPTF, BSP, ORFS,

- Material: AISI304/1.4301, AISI316L/1.4404

Stainless Steel Braided PTFE Hose

Hydraxio’s SS braided PTFE hose asssembly has been field tested and engineered specifically for the chemical applications in the oil and gas industry. Engineered and manufactured from high quality 316 stainless steel braided that protects the PTFE lined. 4 to 1 safety rating 3000 PSI working pressure and burst pressure rating 12,000 PSI. On request we can provide custom lengths.

- Standard: SAE 100 R14

- Hose Size: 1/4, 3/8″ & 1/2″

- Working Pressure: 3,000 PSI

- Burst Pressure: 12,000 PSI

- Working Temperature: -40℃ to +260℃

- Material of Wire Braids: SS 304, SS 316

- Inner Hose: PTFE, FEP

- Hose Fittings: JIC Female, Tube Stub, NPT Male

Technical Support & Solutions

At Hydraxio, we pride ourselves on our comprehensive expertise in engineering and design. From the initial concept to the final product, our team is equipped to transform your ideas into tangible, high-quality hydraulic solutions. Our commitment to innovation ensures that we deliver not just products, but value-driven solutions tailored to your needs.

Free Drawings

Taiored Solutions

Technical Support

Pressure Rating Chart

Hydraxio: Grow Your Market Share with Our Reliable SS Hydraulic Fittings & Solutions

With over 20 years of industry leadership, Hydraxio specializes in the manufacture of stainless steel tube and hose fittings. Our reputation is built on a foundation of exceptional team expertise, cutting-edge technology, rigorous quality control, robust production capacity, and unparalleled professional service.

Widely recognized by global hydraulic & industrial wholesalers, distributors, and OEMs across sectors including hydraulic, pneumatic, oil & gas, chemical, marine, and shipbuilding, our products are synonymous with reliability and quality. We also provide OEM service to major worldwide hydraulic fitting manufacturers, helping them reduce production costs and gain more market share.

Hydraxio continues to thrive in the high-quality overseas market, consistently meeting and often exceeding customer expectations. As a dependable and respected supplier of stainless steel hydraulic fittings, we remain committed to innovation, quality, and customer satisfaction.

Certificates

ISO 9001:2015

ISO 14001:2015

Why Choose us

State of The Art Facilities

Leveraging cutting-edge facilities and equipment, Hydraxio crafts industry-leading stainless steel hydraulic fittings. Our seasoned supervisors, with over 10 years of experience, guide a unified team focused on quality, efficiency, and a shared goal of 100% customer satisfaction. warehouse, shipping, and quality control-have specific objectives that contribute to our overall goal of 100% customer’s satisfaction.

Professional Service

As a professional manufacturer, our engineering department can provide technical service. Like new products designing, CAD drawings and technical advice. Our overseas sales department are 100% well trained with strong industry & product knowledge and service awareness, who can make a quick response within 24 hours to greatly improve the communication efficiency.

Zero Quality Issues

Choose Hydraxio for precision and reliability. In the high-pressure world of hydraulics, our Quality Control Department upholds stringent procedures, ensuring impeccable products. Additionally, a 3.1 material certificate accompanies each shipment, confirming the integrity of our materials.

On-Time Delivery

Trust Hydraxio’s commitment to timeliness. With a 99.99% on-time delivery rate sustained for 3 years, we ensure that consistency is more than a promise—it’s a guarantee. Our ready stock of essential materials enables us to expedite urgent orders without delay.

Testimonials

As a distributor of hydraulic fittings in the USA, I must commend Hydraxio for their exceptional products. The quality and stability of their fittings are remarkable, andtheir prompt feedback and excellent after-sales service made the purchasing experience seamless. Hydraxio has effectively addressed our main concerns, and I strongly recommend them to others in our industry.

Tony, Owner and Purchaser from USA

We are a hydraulic fittings manufacturer in Germany, we highly value Hydraxio for their stable product quality and reasonable pricing. Their fittings have consistently met our standards, enabling us to save costs without compromising quality. We look forward to continued collaboration and recommend Hydraxio to others seeking dependable products at competitive prices.

Robert, head of purchasing from Germany

Frequently Asked Questions

At Hydraxio, we maintain inventory for popular sizes of HY & 43 series hose fittings to cater to immediate demands. Even in cases where specific stock is unavailable, our ready supply of commonly used raw materials ensures that we can expedite production. This enables us to offer exceptionally quick delivery times for urgent orders, affirming our commitment to responsiveness and customer satisfaction.

No, we don't have MOQ requests if the fittings are in stock. For items not in stock, our standard MOQ is 200 pieces per size. For trial orders, we can accommodate lower quantities, such as 100 or 50 pieces, to facilitate the start of our cooperation.

Certainly! We can provide samples for your initial evaluation, and we also have the capability to produce samples based on your specific drawings.

When Hydraxio designs a new hose fitting, the process begins with crimping it onto hydraulic hoses followed by thorough pressure testing. This ensures that all crimp specifications are meticulously evaluated and recorded in our system, reflecting our dedication to quality and performance.

Delivery times vary based on order volume and stock availability. If the fittings are in stock, we can ship within 1 working day post PO receipt. If not in stock, production typically takes 7 to 45 days, depending on the order size.

Our standard terms are 30% down payment in advance, with the balance payable against the copy of the Bill of Lading (BOL). We are open to discussing more flexible payment terms with serious buyers.

Yes, we offer OEM services and have collaborated with several global stainless steel hydraulic fittings manufacturers. By partnering with Hydraxio, you can significantly reduce production costs and enhance your market presence.

When Hydraxio embarks on the design of a new hose fitting, our process begins with crimping the hose fitting onto the hose, followed by the fabrication of the hose assembly. We then conduct an impulse test to evaluate the fitting's performance and durability. The results of this impulse test are meticulously documented, and a detailed report is readily available, reflecting our commitment to quality assurance.

CONTACT FORM

Contact Us Today to Elevate Your Business

Don’t miss the opportunity to transform your hydraulic fittings distribution. Reach out to Hydraxio here. Let’s work together to achieve your business goals.