Find A Reliable Stainless Steel Hydraulic Adapters Manufacturer in China– Hydraxio: Your Trusted Manufacturing Partner

Hydraxio, a leading stainless steel hydraulic adapter fittings supplier in China, serves major hydraulic hose and fittings wholesalers distributors and brand manufacturers(OEM Service) worldwide. We’re committed to reliable quality, timely delivery, and professional service.

Our hydraulic fittings adapters are interchangeable with all majoy brands. Such as Parker and Eaton.

Buy top-quality stainless steel fittings adapters, contact our overseas sales team for a hydraulic adapter fittings catalog.

Wholesale Stainless Steel Hydraulic Adapters Fittings Supplier: Quality, Stability, and Performance You Can Depend On

At Hydraxio, our stainless steel hydraulic adapter fittings types not only meet but also exceed internationally recognized standards such as SAE, JIS, DIN, and ISO. Specializing exclusively in stainless steel, including AISI 304 (1.4401), AISI 316L (1.4404), and AISI 316Ti (1.4571). Trust in our dedication to excellence, as we provide hydraulic tube fittings that set the industry standard.

- Wholesale Price

- Stable Performance

- Quality Raw Materials

- Focused On Stainless Steel Only

- CAD Drawings & Technical Support

- Compliance with International Standards

Types Of Stainless Steel Hydraulic Fittings Adapters

37 Degree JIC Hydraulic Fittings

JIC 37 Degree Fittings: adhering to SAE J514 & ISO 8434-2 standards, feature a 37° cone seat and flare, facilitating connections with corresponding male or female fittings. They can also function as compression tube fittings, with a typical assembly comprising a JIC male fitting body, nut, and sleeve.

- Size: 1/8″ to 2″

- Thread: JIC/JIC, JIC/NPT/NPTF, JIC/NPSM, JIC/BSP, JIC/ORFS

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Cross, Reducer, Plug, Cap

Hydraulic NPT Fittings

The NPT Hydraulic Fitting: an American NPT pipe taper thread, features a 60-degree thread angle and has been a traditional fitting choice for over a century.These tapered thread fittings are commonly employed in various systems, including pneumatic, process, and hydraulic applications.

- Size: 1/8″ to 2″

- Thread: NPT/NPT, NPT/JIC, NPT/NPTF, NPT/NPSM, NPT/ORFS, NPT/BSP

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Cross, Reducer, Plug, Cap

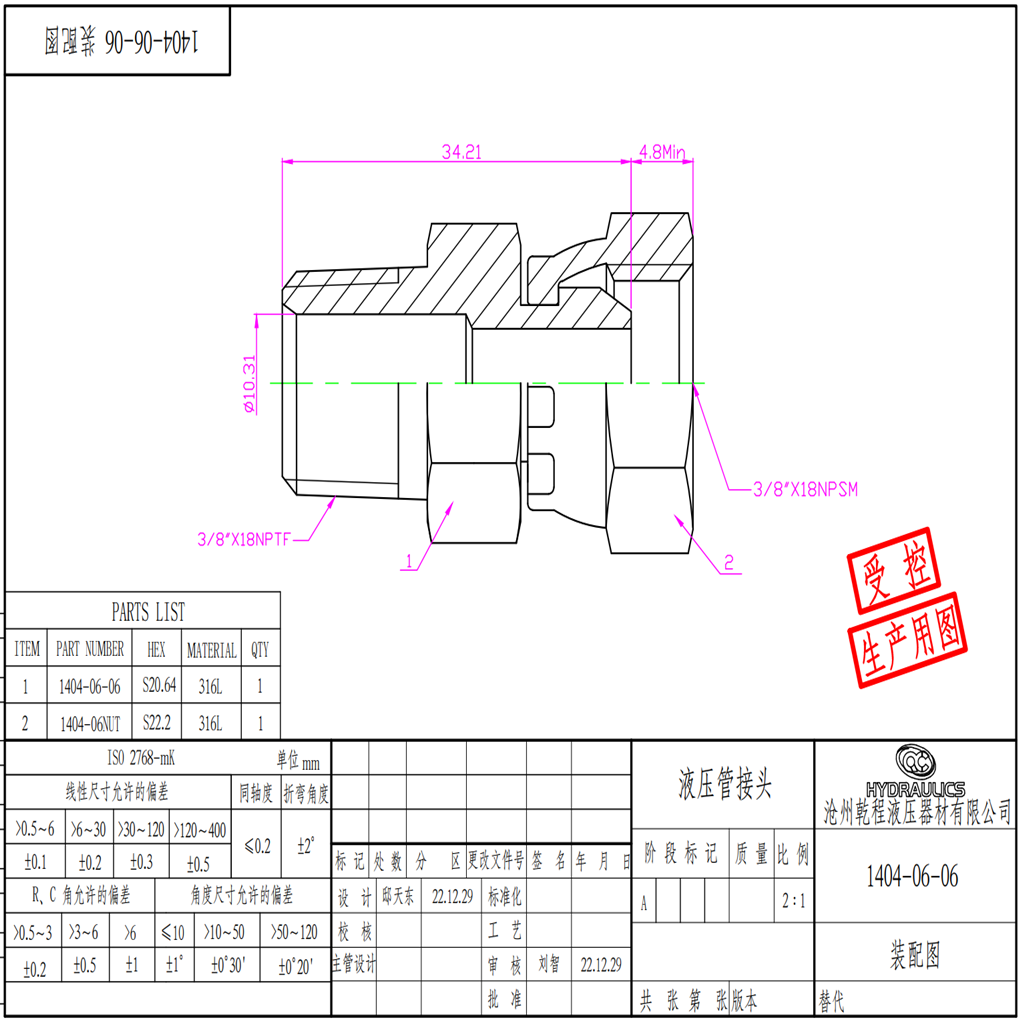

Hydraulic NPSM Fittings

NPT Female Swivel Hydraulic Adapters, also known as NPSM female swivel hydraulic fittings, are specifically designed with a straight thread and a 30° cone. This unique structure allows them to create a reliable mechanical seal when connected with NPTF pipe male fittings. These adapters provide versatility and secure connections in various hydraulic systems. The combination of the straight thread with the 30° cone ensures a robust seal, contributing to the efficiency and integrity of the hydraulic system.

- Size: 1/8″ to 2″

- Thread: NPSM/NPSM, NPSM/JIC, NPSM/ORFS, NPSM/NPT

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Reducer, Plug, Cap

Hydraulic ORB Fittings

O-ring Boss Threads Hydraulic Adapters (ORB Fittings): Defined by the SAE J1926 standard, ORB fittings are integral to hydraulic and automotive systems. These adapters are comparable to JIC fittings but differ by excluding the 37-degree flare.

What sets O-ring boss fittings apart is the incorporation of an O-ring, providing an enhanced sealing mechanism. This addition ensures an exceptionally tight seal capable of withstanding high pressures, making it a preferred choice for demanding hydraulic applications.

- Size: 1/8″ to 2″

- Thread: ORB/ORFS, ORB/ORB, ORB/NPT

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Reducer, Plug, Cap

Hydraulic ORFS Fittings

O-ring Face Seal Fittings (ORFS Fittings): Adhering to the SAE J453 and ISO 8434-3 standards, ORFS fittings are a critical component in hydraulic systems. Unlike traditional connectors, ORFS fittings are featured by a straight thread and a specially machined groove in the face of the male fitting.

This groove is designed to accommodate an O-ring, which can be made from materials such as Buna-N or FKM Viton, depending on the application’s requirements. The inclusion of the O-ring ensures an optimal seal, minimizing the risk of leaks.

- Size: 1/8″ to 2″

- Thread: ORFS/JIC, ORFS/NPT, ORFS/ORFS, ORFS/ORB

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Cross, Reducer, Plug, Cap

Hydraulic JIS Fittings

JIS (Japanese Industrial Standard) fittings are hydraulic fittings commonly used in Japan and other parts of Asia, which connect hydraulic hoses and tubes in machines used in factories, construction sites, and farms. JIS fittings are known for their 30-degree flare angle and BSP threads. This angle helps create a strong seal between the fitting and the hose or tube, preventing leaks when under pressure. JIS fittings come in many sizes, from small ones for low-pressure systems to larger ones for high-pressure use.

- Size: 1/8″ to 2″

- Thread: JIS/JIS, JIS/NPT, JIS/BSP, B/ORB

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Cross, Reducer, Plug, Cap

Hydraulic BSP Fittings

British Standard Pipe (BSP) hydraulic fittings are widely used in hydraulic systems and feature a 55-degree thread angle. These fittings come in two primary styles: BSPP (British Standard Pipe Parallel) and BSPT (British Standard Pipe Tapered). Each has its unique characteristics, sealing mechanisms, and applications.

Key Differences Between BSPP and BSPT Threads

Thread Type: BSPP threads are parallel, while BSPT threads are tapered.

Sealing Mechanism: BSPP requires an additional sealing component like an O-ring or bonded seal, whereas BSPT can form a seal on its own due to its tapered design.

- Size: 1/8″ to 2″

- Thread: BSP/BSP, BSP/NPT, BSP/JIS, BSP/ORB

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows, Tee, Cross, Reducer, Plug, Cap

Weld On Hydraulic Fittings

Metal hose welded fittings are hydraulic components joined to metal pipes or hoses using Tungsten Inert Gas (TIG) welding. They offer a leak-proof and permanent connection, making them ideal for high-stakes applications.

Key Features

- Welding Process: Utilizes TIG welding for a strong and secure connection.

- Leak-Proof: Ensures no leakage, ideal for conveying hazardous or expensive materials.

- Permanent Connection: Suitable for permanent piping systems and applications using ASME pipes.

Applications

- No-Leakage Processes: Such as in pharmaceutical or nuclear industries.

- Hazardous Material Conveyance: Where leaks could have serious consequences.

- Permanent Piping: In industrial and manufacturing settings where the piping configuration is fixed.

Metal hose welded fittings provide a robust and reliable solution for demanding applications, ensuring safety and efficiency across various industries.

- Size: 1/8″ to 2″

- Thread: JIC, NPT, NPTF

- Material: AISI304/1.4301, AISI316L/1.4404, AISI316Ti/1.4571

- Type: Straight, 45 & 90 Degree Elbows

Technical Support & Solutions

At Hydraxio, we pride ourselves on our comprehensive expertise in engineering and design. From the initial concept to the final product, our team is equipped to transform your ideas into tangible, high-quality hydraulic solutions. Our commitment to innovation ensures that we deliver not just products, but value-driven solutions tailored to your needs.

Free Drawings

Taiored Solutions

Technical Support

Hydraulic Adapter Fittings Chart

Hydraxio: Grow Your Market Share with Our Reliable SS Hydraulic Fittings & Solutions

With over 20 years of industry leadership, Hydraxio specializes in the manufacture of stainless steel tube and hose fittings. Our reputation is built on a foundation of exceptional team expertise, cutting-edge technology, rigorous quality control, robust production capacity, and unparalleled professional service.

Widely recognized by global hydraulic & industrial wholesalers, distributors, and OEMs across sectors including hydraulic, pneumatic, oil & gas, chemical, marine, and shipbuilding, our products are synonymous with reliability and quality. We also provide OEM service to major worldwide hydraulic fitting manufacturers, helping them reduce production costs and gain more market share.

Hydraxio continues to thrive in the high-quality overseas market, consistently meeting and often exceeding customer expectations. As a dependable and respected supplier of stainless steel hydraulic fittings, we remain committed to innovation, quality, and customer satisfaction.

Certificates

ISO 9001:2015

ISO 14001:2015

Why Choose us

State of The Art Facilities

Leveraging cutting-edge facilities and equipment, Hydraxio crafts industry-leading stainless steel hydraulic fittings. Our seasoned supervisors, with over 10 years of experience, guide a unified team focused on quality, efficiency, and a shared goal of 100% customer satisfaction. warehouse, shipping, and quality control-have specific objectives that contribute to our overall goal of 100% customer’s satisfaction.

Professional Service

As a professional manufacturer, our engineering department can provide technical service. Like new products designing, CAD drawings and technical advice. Our overseas sales department are 100% well trained with strong industry & product knowledge and service awareness, who can make a quick response within 24 hours to greatly improve the communication efficiency.

Zero Quality Issues

Choose Hydraxio for precision and reliability. In the high-pressure world of hydraulics, our Quality Control Department upholds stringent procedures, ensuring impeccable products. Additionally, a 3.1 material certificate accompanies each shipment, confirming the integrity of our materials.

On-Time Delivery

Trust Hydraxio’s commitment to timeliness. With a 99.99% on-time delivery rate sustained for 3 years, we ensure that consistency is more than a promise—it’s a guarantee. Our ready stock of essential materials enables us to expedite urgent orders without delay.

Testimonials

As a distributor of hydraulic fittings in the USA, I must commend Hydraxio for their exceptional products. The quality and stability of their fittings are remarkable, andtheir prompt feedback and excellent after-sales service made the purchasing experience seamless. Hydraxio has effectively addressed our main concerns, and I strongly recommend them to others in our industry.

Tony, Owner and Purchaser from USA

We are a hydraulic fittings manufacturer in Germany, we highly value Hydraxio for their stable product quality and reasonable pricing. Their fittings have consistently met our standards, enabling us to save costs without compromising quality. We look forward to continued collaboration and recommend Hydraxio to others seeking dependable products at competitive prices.

Robert, head of purchasing from Germany

Frequently Asked Questions

At Hydraxio, we maintain inventory for popular sizes of HY & 43 series hose fittings to cater to immediate demands. Even in cases where specific stock is unavailable, our ready supply of commonly used raw materials ensures that we can expedite production. This enables us to offer exceptionally quick delivery times for urgent orders, affirming our commitment to responsiveness and customer satisfaction.

No, we don't have MOQ requests if the fittings are in stock. For items not in stock, our standard MOQ is 200 pieces per size. For trial orders, we can accommodate lower quantities, such as 100 or 50 pieces, to facilitate the start of our cooperation.

Certainly! We can provide samples for your initial evaluation, and we also have the capability to produce samples based on your specific drawings.

Delivery times vary based on order volume and stock availability. If the fittings are in stock, we can ship within 1 working day post PO receipt. If not in stock, production typically takes 7 to 45 days, depending on the order size.

Our standard terms are 30% down payment in advance, with the balance payable against the copy of the Bill of Lading (BOL). We are open to discussing more flexible payment terms with serious buyers.

Yes, we offer OEM services and have collaborated with several global stainless steel hydraulic fittings manufacturers. By partnering with Hydraxio, you can significantly reduce production costs and enhance your market presence.

CONTACT FORM

Contact Us Today to Elevate Your Business

Don’t miss the opportunity to transform your hydraulic fittings distribution. Reach out to Hydraxio here. Let’s work together to achieve your business goals.