The world of hydraulic fittings and adapters is replete with various standards and thread types, each with its unique applications and advantages. Among these, NPSM (National Pipe Straight Mechanical) and NPT (National Pipe Tapered) threads are two of the most commonly used, especially in the North American market. Understanding the differences between these two types of threads is crucial for selecting the right fittings for your hydraulic systems. This guide aims to provide a detailed comparison, focusing on their characteristics, pressure ratings, and applications.

NPSM Threads: An Overview

Definition and Characteristics

NPSM, which stands for National Pipe Straight Mechanical, features straight threads with a 60-degree angle. Unlike NPT threads, NPSM threads are not tapered.

Sealing Mechanism

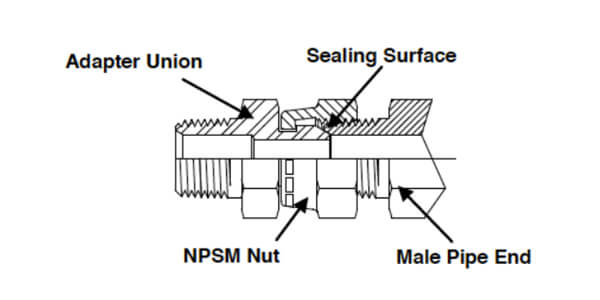

NPSM threads do not inherently form a seal when connected. They require an additional component, usually NPSM male fittings with an O-ring, and female NPSM swivel fittings with a 60 degree cone to ensure a leak-free connection. We can see much more female NPSM swivel fittings than NPSM straight fittings in the market.

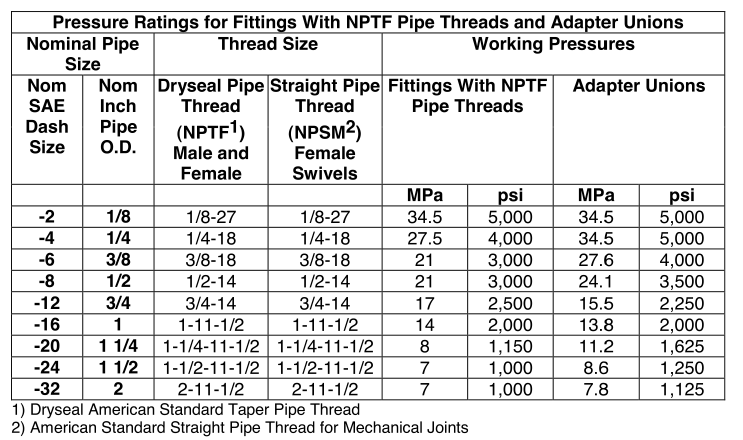

Pressure Rating

The pressure rating for NPSM threads is generally lower than that of NPT threads. This is primarily because NPSM relies on O-rings for sealing, which may not withstand high-pressure conditions as effectively as tapered threads.

Applications

NPSM threads are commonly used in fluid power systems, including hydraulic and pneumatic applications. However, they are not typically used for transporting water or gases unless an O-ring is used for sealing.

Common Names

NPSM threads are sometimes also referred to as NPS, although this can lead to confusion with other types of straight threads.

NPT Threads: An Overview

Definition and Characteristics

NPT stands for National Pipe Tapered, and as the name suggests, these threads are tapered. They also have a 60-degree thread angle, similar to NPSM threads.

Sealing Mechanism

The tapered design of NPT threads allows them to form a seal on their own when tightened. For added assurance, a sealant compound or PTFE (Polytetrafluoroethylene) tape is often used.

Pressure Rating

NPT threads generally have a higher pressure rating, making them suitable for high-pressure applications. The self-sealing nature of the tapered threads contributes to this higher rating.

Applications

NPT threads are versatile and are used in a wide range of applications, including water, gas, and hydraulic systems. They are the go-to choice for many industrial and residential plumbing applications.

Common Names

NPT threads are sometimes referred to as MPT (Male Pipe Threads), FPT (Female Pipe Threads), or simply as pipe threads.

Key Differences Between NPSM and NPT Threads

- Thread Type: The most fundamental difference is the thread type. NPT threads are tapered, while NPSM threads are straight.

- Sealing Mechanism: NPT threads can self-seal due to their tapered design, whereas NPSM threads require an O-ring or another sealing component.

- Pressure Rating: NPT threads generally offer a higher pressure rating compared to NPSM threads. This makes NPT more suitable for high-pressure applications.

- Applications: NPT threads are more versatile and find use in a broader range of applications, including both industrial and residential settings. NPSM threads are more specialized and are commonly used in fluid power systems.

- Sealant Requirement: While NPT threads often use sealants like PTFE tape for added security, NPSM threads almost always require an O-ring for sealing.

Hydraxio is a NPSM and NPT hydraulic fittings manufacturer, please feel free to contact us for more details.