In the world of piping and hydraulic systems, the terminology can sometimes be confusing. Two of the most commonly used terms in the industry are MIP and NPT. At first glance, these abbreviations might seem interchangeable or perhaps related to different standards. However, upon closer inspection, it’s clear that they refer to distinct, albeit related, concepts. This article aims to demystify these terms and shed light on their significance in hydraulic and piping applications.

National Pipe Tapered (NPT)

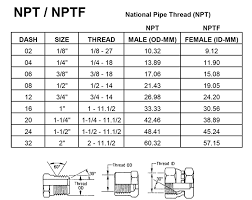

Let’s begin with NPT. Standing for National Pipe Tapered, NPT is a standard defined under the ASME B1.20.1. This American standard provides guidelines for the dimensions and tolerances of tapered threads used in pipes and fittings.

But why tapered threads?

The simple answer lies in their design. Unlike their straight-threaded counterparts, tapered threads provide a more robust and reliable seal. This is particularly true when used in conjunction with sealant materials like Teflon tape, enhancing the connection’s leak-proof properties.

NPT has been around for over a century. Initially crafted for plumbing applications, its versatility and reliability have expanded its usage into the realms of hydraulic and gas conveyance. To fully grasp the nuances of NPT threads, it’s essential to understand their defining features:

Taper Angle: One of the most distinguishing features is the taper angle, which is precisely 1°47’ when measured from the central axis of the NPT fitting.

Crests and Troughs: NPT threads have flat crests and troughs, giving them a distinct appearance.

Angular Configuration: Each crest and trough has a 60° angle between them, contributing to their unique design.

Measurement Standards: The outer diameter of an NPT fitting is typically gauged at the midpoint of the taper.

Pitch: This is essentially the distance between threads and is measured in threads per inch (TPI).

Male Iron Pipe (MIP)

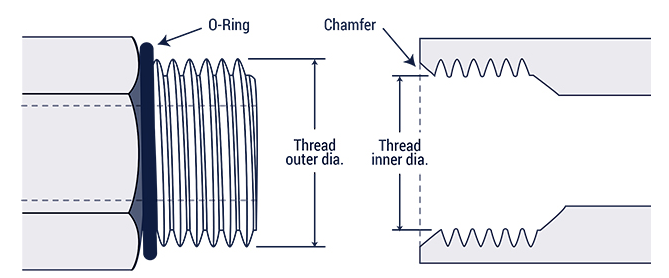

On the other hand, MIP stands for Male Iron Pipe. It’s a national pipe parallel thread, a MIP fitting creates a seal with FIP fittings using an O-ring(MIP with an O-Ring, FIP with a port). Although “iron” is in its name, MIP can also refer to other building materials, including copper and steel. To complete the connection, there’s the FIP, or Female Iron Pipe, which naturally pairs with the MIP.

Hydraxio: Your Go-To Source for MIP & NPT Fittings

For those in the hydraulic and plumbing sectors, understanding the differences and applications of MIP and NPT is crucial. Whether you’re setting up a new system, maintaining an existing one, or planning an upgrade, ensuring you have the right fittings is paramount.

If you find yourself in need of MIP, NPT, or any other hydraulic fittings, Hydraxio is here to assist. With a reputation for quality and expertise, we ensure that you get the best fittings for your specific needs. Don’t hesitate to reach out if you have any questions or demands. Our team is always ready to provide guidance and supply the necessary components to ensure your systems run seamlessly.