In the industrial machinery and hydraulic systems, hydraulic fittings play a vital role. They ensure seamless connectivity and prevent leakages. Among the plethora of fittings available, JIC (Joint Industry Council) fittings stand out due to their unique design and functionality. In this blog post, we’ll explore the JIC fittings chart, offering insights into sizes, applications, and the differences between JIC and other fittings.

1. What are JIC Fittings?

JIC fittings, meet SAE J514 standard, named after the Joint Industry Council, are widely used in hydraulic systems. They feature a 37-degree flare sealing surface and are known for their reliability and reusability. JIC fittings have become a standard in industries requiring high-pressure fluid control, such as in hydraulic applications.

2. The JIC Fittings Chart: Breaking Down Sizes

For anyone involved in the machinery and hydraulic industry, understanding the various sizes is crucial. Here’s a quick breakdown:

Dash Size 2: Ideal for compact systems with minimal fluid transfer.

Dash Size 3 to 5: Commonly used in medium-sized machinery.

Dash Size 8 to 10: Suitable for larger systems with higher fluid capacity.

Dash Size 14 to 16: Reserved for industrial-scale machinery with significant hydraulic needs.

While these are general guidelines, always refer to the manufacturer’s specifications when choosing the right fitting size.

3. JIC vs. Other Fittings:

A Comparative Analysis

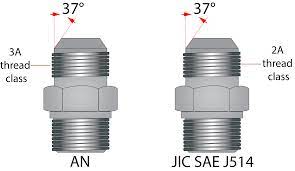

While JIC fittings might appear similar to AN (Army-Navy) and SAE 45-degree flare fittings, there are nuanced differences:

JIC vs. AN (Army-Navy): Both are dimensionally identical, but JIC fittings are typically more affordable due to their less stringent manufacturing tolerances.

JIC vs. SAE 45-degree flare fittings: Although they look alike, they’re not interchangeable. However, certain dash sizes (2, 3, 4, 5, 8, 10, 14, and 16) share identical thread sizes.

4. Why Choose JIC Fittings?

The advantages of JIC fittings are numerous:

Reliability: Their 37-degree flare sealing surface ensures a tight and leak-proof connection.

Reusability: Unlike some other fittings, JIC fittings can be reused, making them cost-effective in the long run.

Versatility: Suitable for a broad range of applications, from automobiles to large-scale industrial machinery.

5. Measuring and Installing JIC Fittings

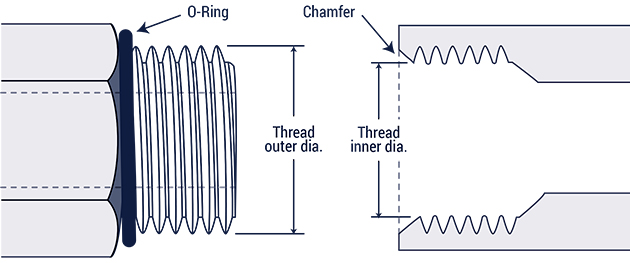

For a perfect fit, it’s essential to measure JIC fittings accurately:

Thread Diameter: Use an I.D./O.D. caliper to measure the diameter.

Thread Pitch: Employ a thread pitch gauge to determine the number of threads per inch or the distance between metric threads.

6. A Word on Quality: The Hydraxio Assurance

If you’re in the market for stainless steel hydraulic fittings, consider Hydraxio. With a legacy dating back to 2007, Hydraxio has been a trusted supplier for wholesale distributors and brand manufacturers in the world of JIC fittings.